Our power project

It will cost many thousands to get grid power to our land, so we're instead going to use the money to set ourselves up with our own independent power sources. We don't need much power as our main requirements are just for lighting, internet and laptops which is around 100W of power when all in use. I estimate that we'll be able to get by on about want about 600W hours of power per day initially.

We'll be using solar for water heating, gas or fire for cooking, a water-wheel for pumping water to four or five meters height for some pressure, and we won't be using a fridge because we have no dairy products and all our vegetables stay fresh by only picking them as we need them. Initially before our solar setup is ready and for things that require high power such as power tools, we've got a GeraMac 3100M 3KW petrol generator which has a Mitsubishi engine made in Japan.

Which ever sources of power are used (solar, hydro, wind etc) storage batteries are required to cater for the varying voltage and current supplies from these different sources and their variable power availability. And this means that a charge controller is required to match the voltage and current of the varying input sources with the varying requirements of the battery depending on its state of charge. Unfortunately it's very expensive to get the kind of hardware that can accept multiple varieties of input sources, so we'll need to have separate sets of batteries and charge controllers for each kind of power source we use (apparently you can parallel up more than one charge controller onto the same battery bank, but I think this would be less efficient).

The load outputs of these charge controllers can then be joined with some power diodes prior to the input of the inverter. Of course more than one inverter can be paralelled up as well since that's simply adding more load, but the AC side of the inverters must never be tied together since their waveforms will be out of phase, so the must run separate AC circuits.

For our small initial requirements, one or two 100Ah batteries and a cheap car inverter will be fine since we're only running LED lights and some computer equipment which all have their own power regulation. I've ordered this cheap 200W model for US$20 which should do the trick.

Contents

Solar

If we consider a worst-case of about four hours of sun per day (which is about right for winter in Rio Grande do Sul) and we want at least 600W hours of power per day then we need at least 150W of panels initially. I'd like to double this reasonably soon and eventually have 1KW of panels so that we can afford to be less frugal with our power, for example by beaing able to keep the computers running when we're not using them so that we can receive incoming calls etc.

We're going to start with a basic 152W kit like this (I also found this one which is a bit cheaper). Building our own panels from the a kit of individual cells gets the price down to around R$2.40 per Watt which is about half of the best prices available in Brazil for ready-made solar panels.

Having our panel mounted on or near the house isn't really very practical in our situation because we're in a bit of a valley and also have many tall trees near by on all sides. Since we have installed a long power cable up to the top of a near by hill for our rural net connection it seems a practical choice to also use that location for our solar panel.

The only problem with this is that we don't want the net hub and router to be constantly on, we want to be able to turn it on and off from the house, but if the panel, battery, charge-controller and inverter are all situated at the remote end of the power cable we can't simply connect or disconnect the power from the net circuit like we could if it were located at the house end.

A reasonably simple solution could be to put a switch at the house-end of one of the spare pairs in the LAN cable. The switch would be used to control a Solid-state relay in the middle pole that activates the hub, and another at the end that activates the router. Only a very low voltage and current then needs to be running through the LAN pair with the switch on it.

Soldering the cells together

I watched this video to learn how to assemble the cells into a functional panel. The first step is to solder the tabbing wire onto the backs of all the cells; each cell is 0.5 volts with the backs positive and the fronts negative, so the idea is to wire all forty cells in series which makes a panel with a maximum output of 20 volts and a nominal output of around 16 volts. This output is then feed into the charge controller which adjusts it to suit the battery and load state.

|

|

|

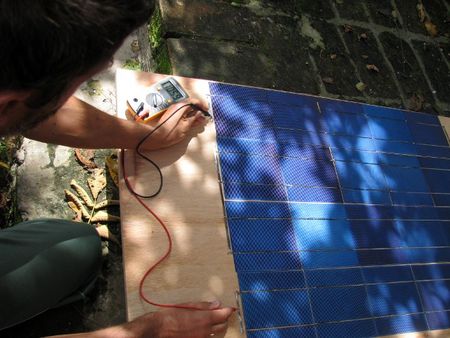

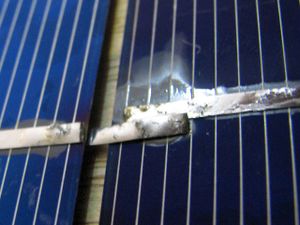

Next I started soldering the cells together into groups of five in series by attaching the tabbing wire that had previously been soldered to the backs to the fronts. One problem that came up with this procedure was that I discovered that I actually have three different types of panels! they're all the same size, but there's two slightly different widths between the connection strips, which meant I had to do some dodgy connecting of some of the cells as shown in the second picture below. The final pictures show a voltage measurement on a series of ten cells which is reading correctly at just over 5 volts.

|

|

|

|

I've now got all four rows of five cells soldered together to make the first panel. I temporarily joined them to test the voltage and it's looking good at 10.59 volts :-) The cells are incredibly fragile and I've broken some small bits of some and have some cracks in others, it's like trying to solder together slim potato chips! Not all cells are quite as fragile as this though, one of the three types I've got feels a lot sturdier, so I hope that

the next set of forty I purchase will all be the same and of the more sturdy type.

Assembling the panel

First I got a large sheet of weather-proof ply wood and got it chopped into four equal pieces of 80cm by 120cm which is enough for three panels (I only have enough cells for two panels so far though). Each cell actually only needed to be 80x94 though so these were then cut a bit more.

I then cut four long pieces of the ply 6cm wide and another four 5cm wide pieces to form a frame for the glass to sit in. I used a G-clamp to hold the frame pieces in position while drilling the screw holes, and to hold it together tightly while putting each screw in to help ensure that its water-tight, and then Beth put silicone sealant into the remaining cracks before painting it.

|

|

|

Charge controller

Another requirement no matter what power technologies you're using is the charge controller which is best to be a good one using MPPT technology so that we get the most out of our energy sources and batteries. Unfortunately MPPT systems are too expensive here in Brazil, so we'll need to settle for a cheaper PWM system such as the SML-25 or SML-60 from MovTec here in Curitiba (Rua Carmem Maito Stinglin, 80, ph. 30145114).

|

|

| SML-60 | SML-25 |

We got the charge controller today. We decided on the SML-60 because we'll be running a 12V system which means that the SML-25 would only be able to handle 300W which is less than another one of our current 152W sets of cells. The SML-60 can handle 720W which means four of or 152W modules will be no problem at all for the unit to handle.

I think that sometime in the near future it would be worth investing in a proper MPPT charge controller because then we can efficiently utilise power from any source regardless of the voltage (as well as getting the most out of our solar cell's output as well). Not only does the MPPT charge controller ensure that no portion of the input power is wasted, it also dynamically tests the characteristics of the panel which changes as the light conditions change to ensure that the current and voltage being drawn from the panel are at the most optimal efficiency - i.e. the Maximum Power Point.

Battery

We've been looking for a battery suitable for using with our solar panel and whatever other sources of pwer we end up using and the charge controller, but we've had a lot of trouble finding anything for a practical price. Then when we were going to a cafe to meet one of Beth's friends we saw a small battery shop on the other side of the road, so we decided to pop in and ask if they had anything, or if not, if they knew of anywhere we could go. Well it turned out that the place was actually very large inside and had a huge range of batteries including the exact kind we were looking for at a good price :-) and better still it turns out that the owner travels to Canela each weekend and said he can drop it off at the Pensão for us! This was really good luck because it weights over 27Kg and batteries require a special expensive courier service to transport. We got a 115Ah Freedom DF2000 battery for R$440.

Wind & Water

We'll eventually get a small wind turbine and water wheel set up, but we'll start with the solar and work on these later. The common factor in both of these is the generator. I want to get in to building my own after I downloaded Energy Creator's DVD and found that building really efficient generators of a few hundred watts of power is totally doable and quite cheap.

Free energy

After reading some of the 2600 page Practical Guide to Free-Energy Devices eBook, I really want to try some of the simpler designs out for myself.

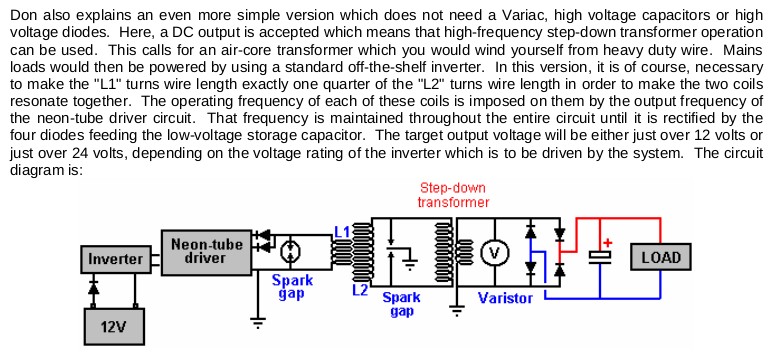

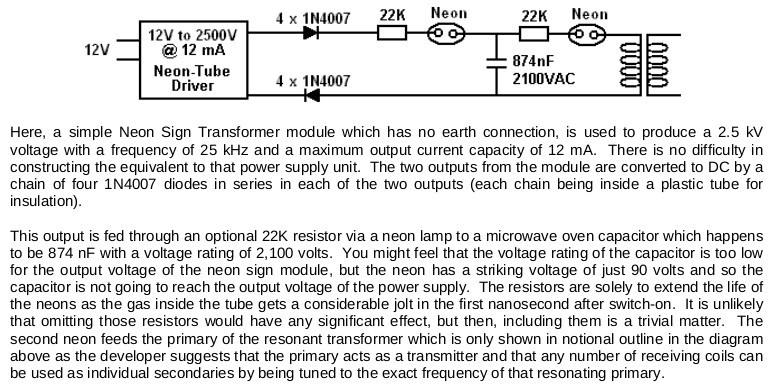

The first being one of Don Smith's designs on page 236:

The second is another of Don Smith's designs on page 248:

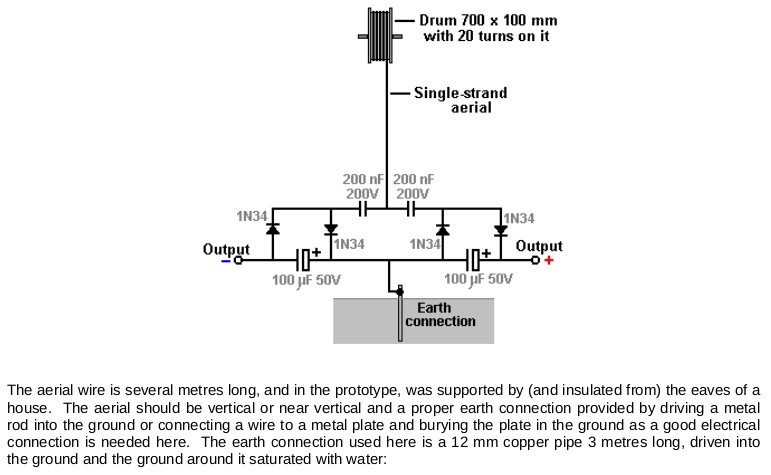

And I've always found the Tesla Aerials pretty interesting which are discussed starting on page 586.

|

Whiteboard notes from 2011 |

See also

- Moving on to our land

- Our rural net connection

- Energy

- Gravity light - cool crowd-sourcing project for creating lighting from a lifted weight