Difference between revisions of "Our second house"

(start documenting) |

(→Floor & frame base) |

||

| Line 24: | Line 24: | ||

|[[File:FoundationMethod.jpg|290px]] | |[[File:FoundationMethod.jpg|290px]] | ||

|[[File:FoundationPipesFinished.jpg|452px]] | |[[File:FoundationPipesFinished.jpg|452px]] | ||

| + | }} | ||

| + | |||

| + | Next we put three large 12.5x5 pieces across each pair, and then five 12.5x2.5's along the whole length on top of these. We used short pieces of 5x8 to keep them spaces properly and to connect them down to the 12.5x5's. We used 22x54 nails to connect the 5x8's to the 12.5x5's and 19x34's to connect the 12.5x2.5's to the 5x8's. Getting all the 12.5x2.5's nice and vertical and in the correct horizontal position can be tricky, so we put a horizontal piece of 12.5x2.5 on each end first (using 17x27 nails) to make a kind of box before measuring, cutting and connecting all the pieces of 5x8. | ||

| + | {{table | ||

| + | |[[file:FoundationFattiesDone.jpg|452px]] | ||

| + | |[[File:FoundationDone.jpg|452px]] | ||

| + | }} | ||

| + | |||

| + | '''Note:''' I think on the next house we'll go the more western style of having a grid of just 12.5x5 all at the same level, instead of having 12.5x2.5's on top of 12.5x5's. Having the large ones on both directions makes it easier and gives more options for connecting the frame. | ||

| + | |||

| + | == Floor & frame base == | ||

| + | To do the floor, we positioned all the pieces first to find ones that lined up nicely and remove ones that were too rough or bent. Then after nailing an end one in place, we then sat on top of the loose ones, one of us on each side and nailed one end each, pushing each piece tightly into the prior one, we used three 17x27's for each line formed by the 12.5x2.5's below. | ||

| + | |||

| + | The frame base is the 5x8's laid down around the edge to support the frame. These may be on top of the floor boards or around the edge of them depending on the foundation design. ours are on top. They should be bolted to solid 5x8 or large foundation pieces, in our case since we only have the 12.5x5's below we needed to add some 5x8 pieces to bolt the frame base pieces into. If the wood is very bent like ours, then first you need to secure the end points in exactly the right place and then force the middle into position and clamp it to drill the bolt hole. | ||

| + | |||

| + | Note the gaps in the corners, these are for the vertical frame pieces which will be an L-shape, you can either measure or position some short bits of 8x5 in place to get these gaps the right size. The diagram below shows the view downwards onto a corner demonstrating how the 8x5's are formed into an L-shape. This is done both for strength and to ensure that all the sides have a full 8cm width of vertical frame to attach to. In our case it also helps us make verticals that are less bent! | ||

| + | {{table | ||

| + | |[[File:Floor2.jpg|452px]] | ||

| + | |[[File:FrameCorner.jpg|412px]] | ||

}} | }} | ||

Revision as of 21:14, 17 February 2016

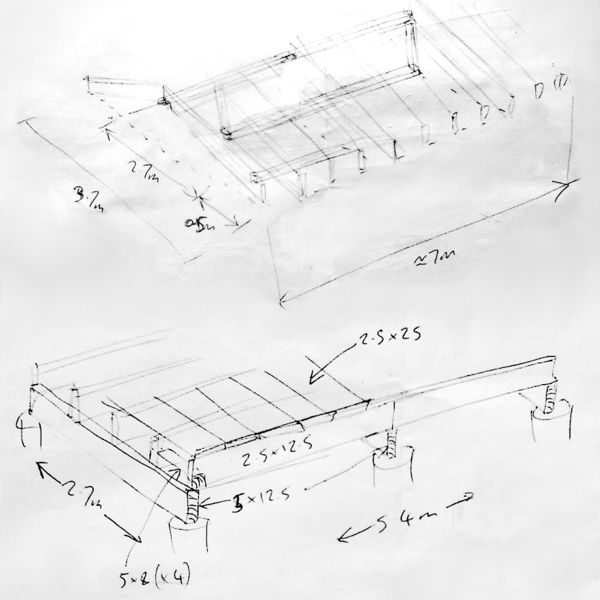

Plans

This house is a pretty similar design to our first one, a tiny 2.7x5.4 metre single room, so we didn't feel that much of a plan was necessary, but we did have to scribble a table napkin plan to calculate what materials we needed. We're doing a few things like the roof structure a little bit differently to avoid the problems we ran across in the first house, and we decided to buy ready made window frames with shutters this time - we got four, but we're not sure where they're going to go yet, we're planning a lot of it as we go :-)

Note: Be sure to buy about 25% more wood than necessary because a lot of the wood from these cheap places is bent or damaged,

Preparing the work area and wood

Another important aspect in the planning stage is to decide where your work area is going to be, i.e. where all the wood will be stored that is easily accessible from the house with plenty of space for cutting etc. Ensure the truck can easily reach your area and park along side it to unload the materials there and has space to turn around etc. Unfortunately our area is too uneven and they guy didn't want to bring the truck down there so we have to manually carry the materials down the hill about twenty metres.

We bought really cheap wood (pine and eucalyptus) which is untreated, so the first thing we do is paint it with burned oil which is really good at stopping bugs from eating it. You can get burned oil for nothing or dirt cheap at most gas stations.

Foundations

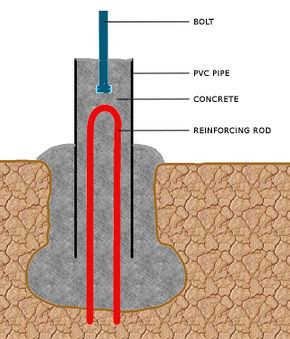

We made six foundations poles using PVC pipe filled with concrete as shown in the first image below. Unfortunately the south-east (closest to Vladimirs place) and the north-west poles have no reinforcing - because we completely forgot about it! And the middle pipe on the south side goes all the way to the bottom of the hole, but apart from those problems all went well. We used 75Kg of cement, 150kg of sand and an extra 50kg of large stones. The cement is pretty bad quality as it's a couple of years old, and the sand too is from the river containing a fair bit of mud, so this concrete wouldn't be suitable for structure, but hopefully it'll be fine for foundations where the force is almost all downwards and it's contained within the PVC pipe to prevent it from bending if any cracks were to form in it.

Next we put three large 12.5x5 pieces across each pair, and then five 12.5x2.5's along the whole length on top of these. We used short pieces of 5x8 to keep them spaces properly and to connect them down to the 12.5x5's. We used 22x54 nails to connect the 5x8's to the 12.5x5's and 19x34's to connect the 12.5x2.5's to the 5x8's. Getting all the 12.5x2.5's nice and vertical and in the correct horizontal position can be tricky, so we put a horizontal piece of 12.5x2.5 on each end first (using 17x27 nails) to make a kind of box before measuring, cutting and connecting all the pieces of 5x8.

Note: I think on the next house we'll go the more western style of having a grid of just 12.5x5 all at the same level, instead of having 12.5x2.5's on top of 12.5x5's. Having the large ones on both directions makes it easier and gives more options for connecting the frame.

Floor & frame base

To do the floor, we positioned all the pieces first to find ones that lined up nicely and remove ones that were too rough or bent. Then after nailing an end one in place, we then sat on top of the loose ones, one of us on each side and nailed one end each, pushing each piece tightly into the prior one, we used three 17x27's for each line formed by the 12.5x2.5's below.

The frame base is the 5x8's laid down around the edge to support the frame. These may be on top of the floor boards or around the edge of them depending on the foundation design. ours are on top. They should be bolted to solid 5x8 or large foundation pieces, in our case since we only have the 12.5x5's below we needed to add some 5x8 pieces to bolt the frame base pieces into. If the wood is very bent like ours, then first you need to secure the end points in exactly the right place and then force the middle into position and clamp it to drill the bolt hole.

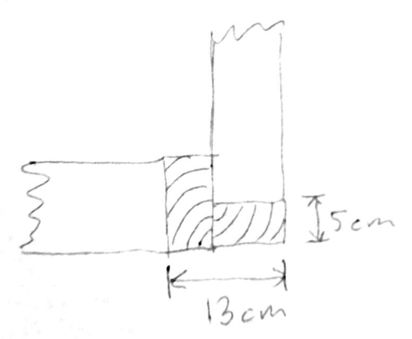

Note the gaps in the corners, these are for the vertical frame pieces which will be an L-shape, you can either measure or position some short bits of 8x5 in place to get these gaps the right size. The diagram below shows the view downwards onto a corner demonstrating how the 8x5's are formed into an L-shape. This is done both for strength and to ensure that all the sides have a full 8cm width of vertical frame to attach to. In our case it also helps us make verticals that are less bent!